Projects

Aerostructural Optimization of Large Wind Turbine Rotors

Efficient and large-scale renewable energy systems are of fundamental importance to tackle the upcoming climate crisis. The MDO Lab, funded through the ARPA-E ATLANTIS program, is part of a multi-university effort aimed at the development of a novel computational framework for the multidisciplinary control co-design and optimization of floating wind turbines. The state-of-the-art software will enable the design of lighter and more efficient systems that have the potential to provide a large amount of carbon-free and low-cost energy for the US and global market.

Offshore wind energy alone could satisfy a large part of the US domestic demand, but we currently lack of the technology for cheap energy extraction. The areas with the highest wind potential are located in deep waters, where the proven fixed-bottom offshore technology is not a viable solution. Recent experimental floating systems are demonstrating the operational feasibility of this new technology, but the turbine design they are based on is still closely related to their on-shore counterparts. In order to achieve cost and efficiency goals, radical new wind turbine configurations have to be developed by taking advantage of modern control strategies and an accurate prediction of complex system multi-physics interactions.

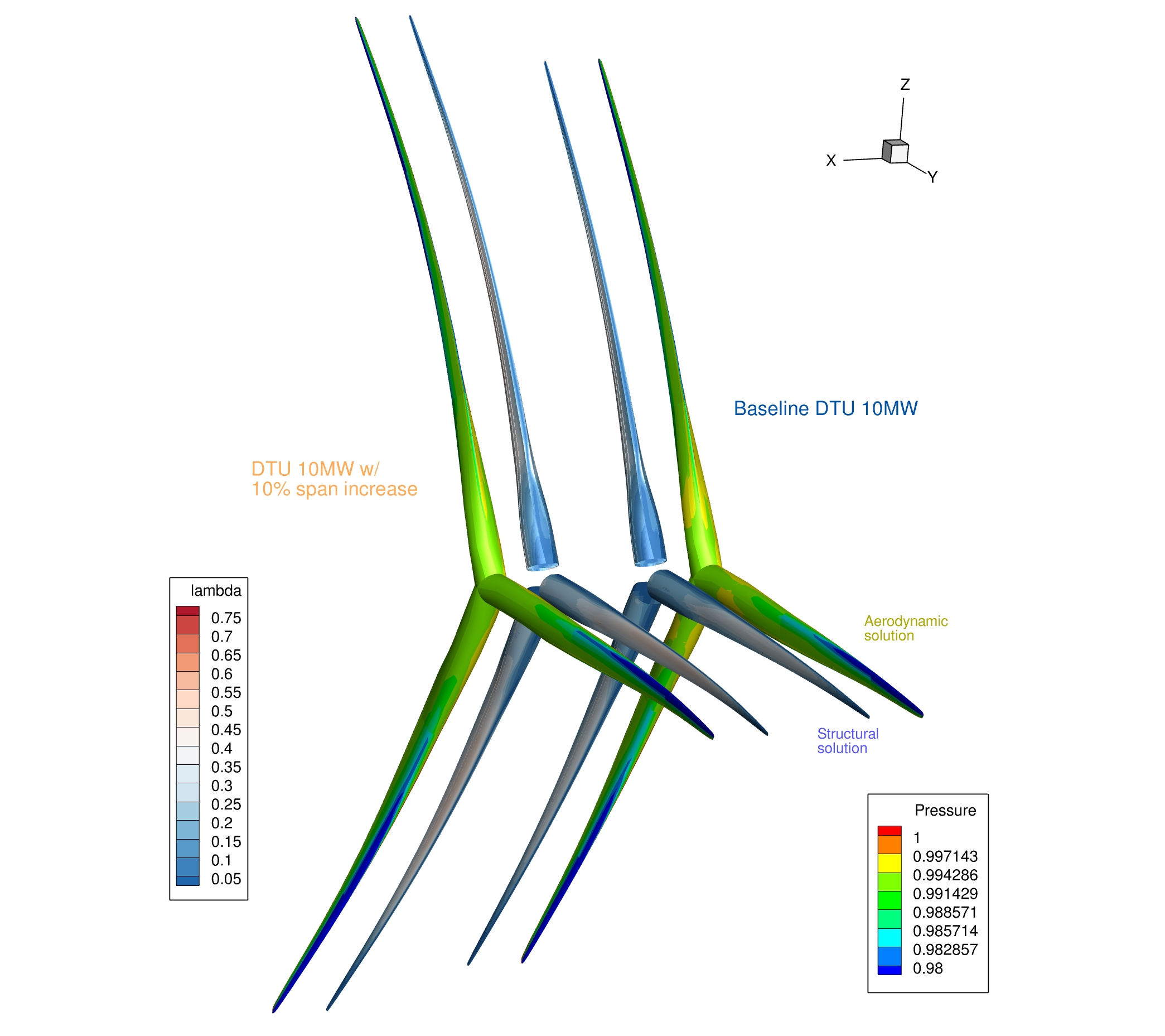

We are extending the capabilities of the high-fidelity tools developed at the MDO Lab to model large flexible wind turbine rotors, whose performance is strongly dependent on the tradeoffs between the flow behavior around the blades and their structural response to aerodynamic and inertial loads. The novel rotor shapes and structural layouts we aim to develop will maximize the energy extraction performance while minimizing the mass of the system. The resulting configurations would lead to a substantial reduction in the cost of energy. Our short-term goal is to perform the first-of-a-kind aerostructural design optimization of a wind turbine rotor using high-fidelity analysis software. The framework will be then extended to include multiple components and additional physical models. This will enable the realistic simulation of a wider range of design conditions and system dynamics, both highlighting the benefits of high-fidelity modelling and fostering the application of floating wind energy technology.